What does a carburetor backfire flame arrestor do – Delving into the realm of automotive safety, we explore the enigmatic device known as the carburetor backfire flame arrestor. This unsung hero plays a crucial role in preventing potentially catastrophic engine backfires and explosions, ensuring the well-being of both vehicles and their occupants.

In this comprehensive guide, we unravel the mysteries surrounding carburetor backfire flame arrestors, shedding light on their working mechanisms, components, maintenance, and diverse applications. Join us as we delve into the fascinating world of engine safety, where every detail matters.

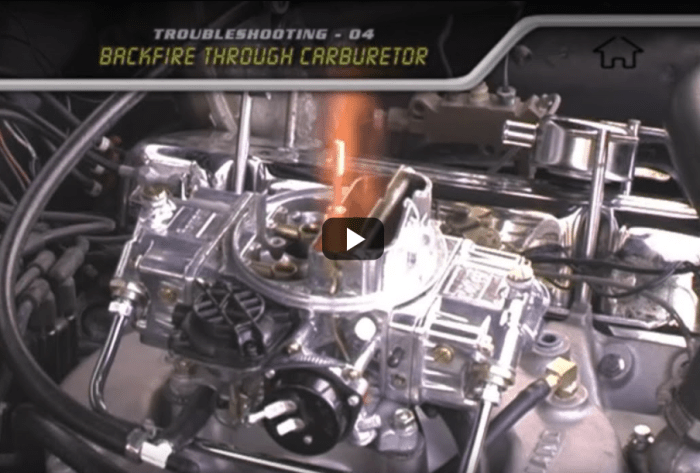

Carburetor Backfire Flame Arrestor Overview

A carburetor backfire flame arrestor is a safety device installed in the carburetor of an internal combustion engine to prevent backfires and explosions. It is designed to quench flames and dissipate heat, ensuring the safe operation of the engine and preventing potential hazards.

Backfire flame arrestors have been used for over a century, with early designs dating back to the early days of internal combustion engines. The first flame arrestors were simple devices made of wire mesh or perforated metal, but over time, they have evolved to become more sophisticated and efficient.

Types of Carburetor Backfire Flame Arrestors, What does a carburetor backfire flame arrestor do

- Mesh-type flame arrestors:These arrestors consist of a fine mesh screen that traps and extinguishes flames.

- Perforated-plate flame arrestors:These arrestors have a series of small holes that allow air to pass through while preventing flames from propagating.

- Combination flame arrestors:These arrestors combine both mesh and perforated-plate elements for increased effectiveness.

Working Mechanism of a Carburetor Backfire Flame Arrestor: What Does A Carburetor Backfire Flame Arrestor Do

A carburetor backfire flame arrestor works by quenching the flame front and dissipating heat. When a backfire occurs, the flame travels through the carburetor and into the flame arrestor. The mesh or perforated plate in the flame arrestor creates a series of small passages that break up the flame front and reduce its velocity.

The flame arrestor also absorbs heat from the flame, which further reduces its temperature and prevents it from propagating. The combination of flame quenching and heat dissipation effectively prevents the backfire from reaching the fuel tank or other flammable components, ensuring the safety of the engine and its surroundings.

Components and Design of a Carburetor Backfire Flame Arrestor

A carburetor backfire flame arrestor typically consists of the following components:

- Mesh or perforated plate:This is the primary flame-arresting element.

- Housing:This encloses the mesh or perforated plate and provides a mounting point for the flame arrestor.

- Gasket:This seals the flame arrestor to the carburetor to prevent air leaks.

The design of a carburetor backfire flame arrestor is critical to its effectiveness. The mesh or perforated plate must have the appropriate pore size and thickness to effectively quench flames while allowing sufficient airflow for engine operation. The housing must be strong enough to withstand the pressure and heat generated by backfires, and the gasket must provide a leak-proof seal.

Maintenance and Inspection of a Carburetor Backfire Flame Arrestor

Regular maintenance and inspection of a carburetor backfire flame arrestor are essential to ensure its proper functioning and the safety of the engine. The flame arrestor should be inspected regularly for damage, corrosion, or blockages. Any damaged or worn components should be replaced immediately.

The frequency of inspection and maintenance depends on the operating conditions of the engine. In general, flame arrestors in high-performance engines or engines operating in harsh environments may require more frequent attention.

Applications of Carburetor Backfire Flame Arrestors

Carburetor backfire flame arrestors are widely used in a variety of applications, including:

- Automotive engines:Flame arrestors are essential for preventing backfires in automotive engines, especially in high-performance vehicles.

- Marine engines:Backfire flame arrestors are required by law on marine engines to prevent explosions in enclosed engine compartments.

- Industrial engines:Flame arrestors are used in industrial engines to protect against backfires in hazardous environments, such as chemical plants and refineries.

Questions and Answers

What is the primary function of a carburetor backfire flame arrestor?

A carburetor backfire flame arrestor’s primary function is to prevent the propagation of flames from the carburetor into the intake manifold, thereby mitigating the risk of engine backfires and explosions.

How does a carburetor backfire flame arrestor work?

A carburetor backfire flame arrestor employs a series of baffles and screens to quench flames by disrupting their laminar flow and cooling them below their ignition temperature.

Why is regular maintenance of a carburetor backfire flame arrestor important?

Regular maintenance of a carburetor backfire flame arrestor is crucial to ensure its effectiveness and prevent potential engine damage. Inspections should be conducted periodically to check for any signs of wear or damage, and cleaning or replacement should be performed as necessary.